Our solutions for a sustainable management of resources

Our references

Our news

Press release

Water

Waste

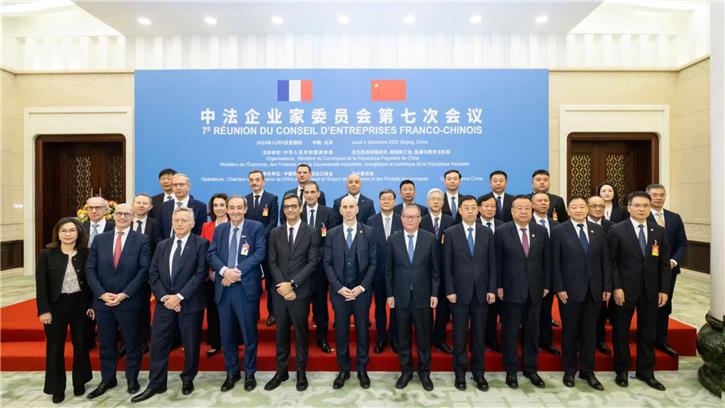

SUEZ reaffirms long-term commitment to China with new collaborative initiatives in Jiangsu and Shandong provinces

On President Emmanuel Macron’s state visit to China, SUEZ signed new collaborative initiatives...

Press release

Waste

Recycling and recovery

SUEZ signs new waste project with Chongqing partners to recycle organic solvents for reuse

SUEZ and its partners1 have signed an agreement to invest approximately RMB 170 million (20.4...

Press release

Sustainable development

World Biodiversity Day: SUEZ is committed to preserving and regenerating biodiversity in Asia and beyond, at its sites and with its customers

50% of the world’s GDP depends on services provided by nature and biodiversity. To help protect...